STRONGER. LIGHTER. SMARTER. FASTER.

Design the New Standard — from the Inside out.

THE INSIDE OUT

EVOLUTION

STARTS HERE

Gyroids were the beginning — Spherene is the next Evolution.

Adaptive Density Minimal Surfaces (ADMS) enable lighter, stronger, and smarter parts — directly inside your CAD.

Spherene set a new benchmark for smarter, high-performance internal structures in additive manufacturing. Quick and Easy design.

→ Discover Why Leading Companies Choose ADMS over TPMS (Video)

WHY COMPANIES ARE REPLACING TPMS WITH ADMS

Traditional lattices are static. ADMS is isotropic, it adapts and is very easy to design.

While TPMS geometries repeat uniformly, Spherene’s Adaptive Density Minimal Surfaces (ADMS) respond intelligently to stress, heat, and load, maintaining isotropic performance throughout the part.

Spherene turns geometry into intelligence.

Its adaptive structures optimize strength and stiffness exactly where needed — creating components that are lighter, stronger, and more efficient, while reducing material use, cost, and environmental impact.

Our metamaterial technology redefines design and manufacturing.

By replicating bulk material behavior and continuously adjusting density, ADMS shortens design cycles by up to 10× and enables engineers to produce smarter, more sustainable components — from aerospace to biomedical applications.

FROM INSTALLATION TO INNOVATION IN FEW STEPS

to your account

Login or Sign Up to create your Spherene account and activate your free trial instantly.

the Plugin and Install

Available for Rhino / Grasshopper, nTop, and Autodesk Fusion. More to come. Stay Tuned!

Generate the Inside

SMARTER DESIGN. BETTER MANUFACTURING.

-

Fast, intuitive, and easy to use design workflow.

-

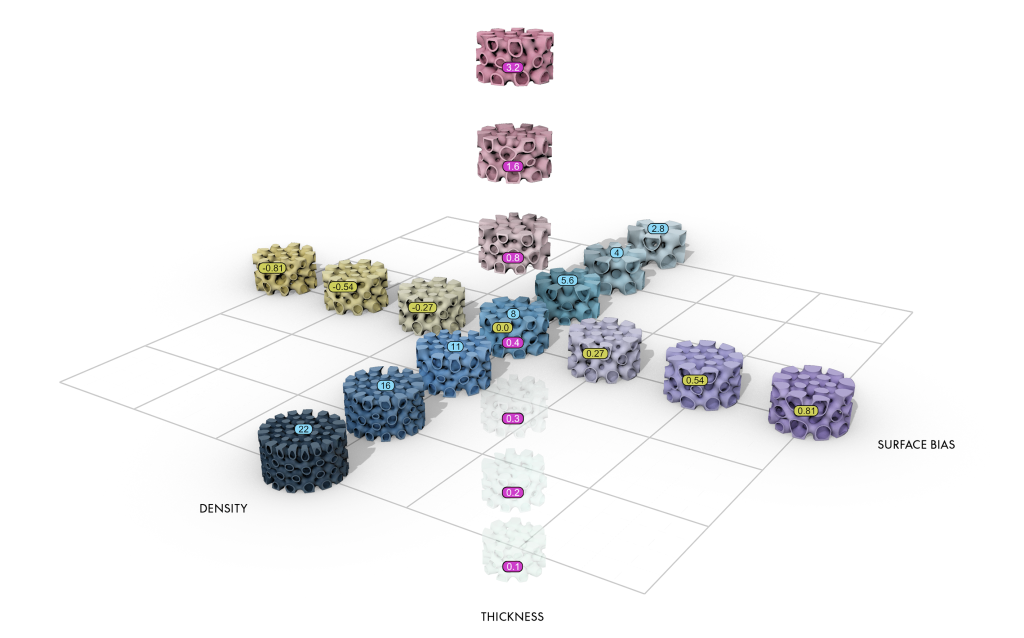

Precisely control material density, thickness, and bias.

-

Seamlessly customize with complex cavities and closures.

-

Intelligently generate adaptive shapes completely autonomously.

-

Fast, intuitive, and easy to use design workflow.

-

Precisely control material density, thickness, and bias.

-

Seamlessly customize with complex cavities and closures.

-

Intelligently generate adaptive shapes completely autonomously.

-

Industry’s only truly surface-conformal minimal surface technology.

-

Delivers true isotropy for optimal stress distribution.

-

Adapts seamlessly to any complex 3D geometry.

-

Precisely mimics the behavior of bulk material.

-

Industry’s only truly surface-conformal minimal surface technology.

-

Delivers true isotropy for optimal stress distribution.

-

Adapts seamlessly to any complex 3D geometry.

-

Precisely mimics the behavior of bulk material.

-

Minimizes the need for additional build supports.

-

Greatly enhances thermal dissipation and stability.

-

Reduces overall cost and total production time.

-

Fully compatible with all materials and printing methods.

-

Minimizes the need for additional build supports.

-

Greatly enhances thermal dissipation and stability.

-

Reduces overall cost and total production time.

-

Fully compatible with all materials and printing methods.

WHAT OUR CUSTOMERS HAVE TO SAY

«...clearly addressing one of the cross-cutting themes of the ESA technology strategy, but in a novel way.»

«Spherene has proven highly valuable to Fibrenamics’ R&D in advanced materials and product design. Its generative modelling capabilities enable optimized, complex geometries that enhance efficiency and performance. Integrating Spherene strengthens our commitment to scientific excellence, innovation, and sustainable high-performance solutions.»

«Right after I started using gyroids for printing ski boot liners or TPMS mid-sole designs, we began dreaming of a bubble-type infill structure with variable density and wall thickness that could conform to any shape. Now, Spherene does just that—easy to use in design, fully printable, and highly customizable. Using this unique Swiss software, you’ll get the maximum from your 3D printer.»

«Having explored a few Rhino/ Grasshopper plugins for minimal surface generation, Spherene distinctly stands out. It has a straightforward interface, paired with Spherene's concise tutorials and cloud integration, ensuring rapid iterations of our design studies.»

SIMPLIFIED COMPLEXITY

Spherene transforms complex design at unprecedented speed into a simple, intuitive process.

Spherene’s parameter-driven tools let engineers control density, thickness, and bias to create adaptive internal structures that respond to real-world forces in minutes. With true isotropy and surface-conformal minimal surfaces, Spherene optimizes stress distribution while cutting weight, material, and production time — seamlessly integrating into any CAD workflow to turn complexity into clarity.